Orion Real-Time Decision Support Tool

Real-Time Reliability Assessment

The heat shield of a space vehicle, also known as the thermal protection shield system (TPS), is a vital element and can make or break a successful NASA Space Mission. This effort focused on the development of a user-friendly, real-time executing tool that can be used to enable rapid, risk-informed decisions by non-engineering users, without the assistance of software specialists. The key objective of this effort was to develop and demonstrate a probabilistic-based decision support tool for real-time reliability assessment of the Orion TPS for various trajectories and relevant conditions using PredictionProbe’s (PPI’s) SPISE® Software.

Project Overview

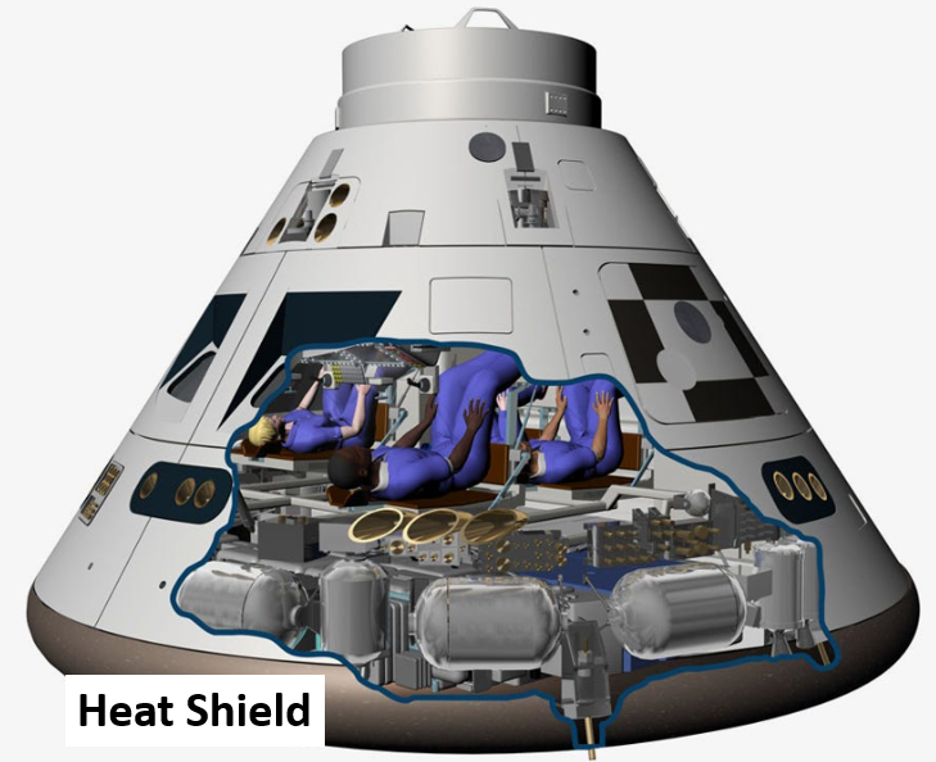

A heat shield is the unique sub-system of a space capsule that is designed to protect the rest of the space capsule, and its human or scientific payload, from the extreme and uncertain temperature and pressure loads encountered during the capsule’s entry into an atmosphere. For the National Aeronautics and Space Administration (NASA) Orion space capsule (Figure 1), the heat shield is designed to withstand temperatures of thousands of degrees, and pressures several times that of the normal atmosphere, during the entry of the capsule into the Earth’s atmosphere. Heat shields typically employ a variety of thermal mechanisms (e.g., conduction, convection radiation, ablation and melting) to accomplish this extremely important objective. The heat shield is usually the only sub-system of the space capsule for which no form of redundancy exists. Hence, even if everything else in the mission goes perfectly, the success of the entire mission ultimately depends entirely upon the success of the heat shield. This piece of equipment is so important, that it is routinely over-designed; in fact, the mission goals and objectives may be limited in order to accommodate this over design.

The Orion space capsule.

STS Columbia.

The NASA Space Transportation System (STS, i.e., “space shuttle”) Columbia (Figure 2) is the most obvious example of a heat shield failure. The vehicle was completely destroyed (February 1, 2003, Figure 3) during re-entry into Earth’s atmosphere because of unforeseen and undetected damage to the tile-based heat shield. The damage was caused by pieces of insulating foam shedding from the fuel tanks during the ascent phase of the mission from Earth two weeks earlier. The Columbia failure grounded all subsequent STS flights for about two and a half years while an in-depth investigation was conducted. The findings, observations and recommendations of the investigation resulted in significant cultural changes throughout the agency and expense increases and operational changes to provide a variety of heat shield inspections for the remaining 21 STS flights through 2011.

STS Columbia’s fatal re-entry.

The overall goals of the current project were to: 1) quantify the reliability of the Orion thermal protection system (TPS, i.e., “heat shield”) to withstand the a wide variety of possible re-entry conditions and thermal loads, and 2) identify the key sensitivities of the predicted reliability to uncertainties and TPS design variables. Within these goals, the objective of this particular effort was to develop and demonstrate a probabilistic-based decision support tool for real-time reliability assessment of the Orion TPS for various trajectories and relevant conditions using PredictionProbe’s (PPI’s) SPISE® Software.

Problem Definition

This effort focuses on the development of a user-friendly, quickly executing tool that can be used to enable rapid, risk-informed decisions by non-engineering users, without the assistance of software specialists. Ideally, the tool can be used by management within the setting of meeting in which decision alternatives need to be quickly evaluated. The tool must provide the specific capabilities of uncertainty/risk analysis, quantification, propagation, decomposition, and management, robust/reliability design methods, and extensions of these capabilities into decision analysis methods. The same decision support technology has also been applied to the spread of a deadly virus.

Such decision support tools must provide whatever are the required capabilities across a potentially wide variety of traditional specialty areas (disciplines) such as aerodynamics, structures, controls, heat transfer, and trajectory analysis. Decision support tools should also perform analyses which span across, and are distinct from, these specialty areas to support the process of making decisions based upon computational simulations. For example, systems integration, multidisciplinary optimization, mission and trade space analyses, life cycle cost analyses, uncertainty/risk analysis and management, robust and reliability design methods, technology assessments, research portfolio analyses, and “system of systems” architecture analyses all fall into this category of capabilities. For convenience, this group of disciplines will simply be referred to collectively herein as Decision Support (DS) methods and tools.

These DS methods and tools are closely related to the processes of systems analysis (SA) and/or systems engineering (SE). The NASA Procedural Requirements, NPR 7123.1, Systems Engineering Procedural Requirements, defines systems engineering (SE) as “a logical systems approach performed by multidisciplinary teams to engineer and integrate NASA’s systems to ensure NASA products meet customer’s needs.” The same document also defines systems approach as the application of a systematic, disciplined engineering approach that is quantifiable, recursive, iterative, and repeatable for the development, operation, and maintenance of systems integrated into a whole throughout the life cycle of a project or program.”

This systems approach includes 17 common technical processes grouped under the headings of System Design Processes, Product Realization Processes and Technical Management Processes. It is expected that, at least, some of the processes should and must take place concurrently. Furthermore, it is expected that numerous passes through each of the 17 processes may occur, with iteration cycles and re-entry points established as appropriate. However, simply utilizing a good SA or SE process does not ensure that all the customer’s requirements can be satisfied within cost, schedule, or safety constraints, or with the tools and methods available. Likewise, satisfying the customer’s requirements does not mean that the results were obtained by a systematic, disciplined engineering approach that is quantifiable, recursive, iterative, and repeatable for the development, operation, maintenance, and disposal of systems. The two aspects of this problem, customer satisfaction and good SA/SE process, are really mutually independent, though correlated. A good SA or SE process should include a negotiation between the developer/provider and the customer, early in project lifetime and throughout, to ensure that a reasonable chance exists to satisfy the customer’s requirements within cost, schedule, and safety constraints. The architecture of a real-time decision support tool must be very flexible and easily reconfigurable to enable all the aspects of DS, SA and SE to be implemented in a user-friendly environment.

PredictionProbe’s Solution

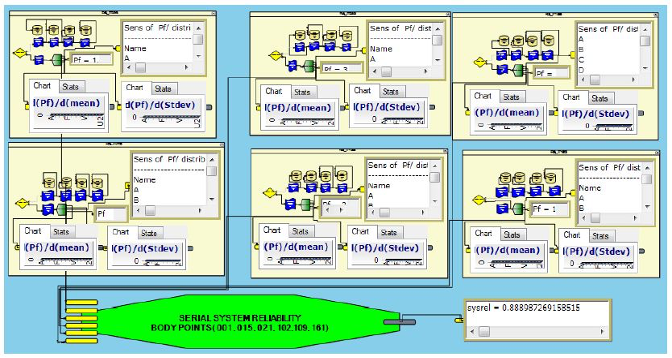

In a related Case Study, the development of a reliability assessment process for the Orion space capsule heat shield is described. The work employed the PPI tool UNIPASS®. For this task, a market survey of probabilistic technology (PT) tools and frameworks was conducted by NASA Langley Research Center (LaRC). The Seamless Probabilistic Integration Software Engine (SPISE®) from PPI was selected for use to create a real-time PT-based decision support framework. The PPI toolset (UNIPASS® and SPISE®) has been found by NASA LaRC in several software comparisons to have the greatest collection of Probabilistic Technology capabilities. In the reliability assessment example, 70 modules were developed and integrated within SPISE® to analyze seven body points (BP) of the Orion heat shield, with two trajectories for each BP and five reliability cases for each trajectory. An uncertainty correction term was used to account for the observed differences between computation and the measured test data. Several failure-mode models and PT analysis methods were compared.

Figure 4.

Illustration of the Orion real-time decision support tool.

About PredictionProbe, Inc.

PredictionProbe, Inc. is a small business and proud provider of an elite offering of world-class predictive technologies, tools, and services that enable decision makers with real solutions for real world challenges. To learn more visit us at: predictionprobe.com

PredictionProbe, Inc. ©2020. All rights reserved.